Sentinel Nuts

Sentinel Nuts are designed to fit the rock. Their straight tapered sides provide good surface contact and ease of placement and removal. Sentinel Nut's precise taper guarantees balance between security and removability consistently, placement after placement.

The wire slings on our nuts come in two lengths. Use the regular sling length Sentinel Nuts for wall climbing, and with quick draws on the crag. The long sling nuts carry well on your climbing harness and their flexible stainless wire slings enable them to reduce rope drag without always requiring the extension of quick draws.

As of 2019 all rights to the Sentinel Nuts design including production and sales have been transferred to Larry Arthur and Mountain Tools. For dealer inquiries including pricing and direct sales please contact larry@mtntools.com or call (831) 620-0911.

Nut Features

Sentinel's straight angle of taper:

Optimizes fit and surface contact in the crack.

Establishes the balance between security and removability.

Sentinel slings:

- Provide length options to enhance free and aid climbing.

- Are made from flexible 7 x 19 stainless steel aircraft wire.

Sentinel features include:

- A mild transverse end taper to accommodate flaring cracks.

- Extra height to maximize fitting range and surface contact.

- The endwise length of 1.5 sizes greater provides half-size fitting.

- Three sizes overlap a normal four-nut range.

- Each nut is individually tested to one-half the rated strength.

Sentinel Nut Sizing

Regular Slings Long Slings Number

Dimension

(inches)Sling

Strength

(kN)Sling

Length

(inches)

Sling

Length

(inches)1

.23 x .37 4 8.0 11.8 2 .28 x .42 5 8.1 12.4 3 .33 x .48 9 8.2 12.7 4 .40 x .56 10 8.3 12.8 5 .48 x .66 10 8.4 12.9 6 .58 x .78 10 8.5 13.0 >7 .70 x .93 10 8.6 13.1 8 .85 x 1.09 10 8.7 13.2 9 1.02 x 1.25 10 8.9 13.3

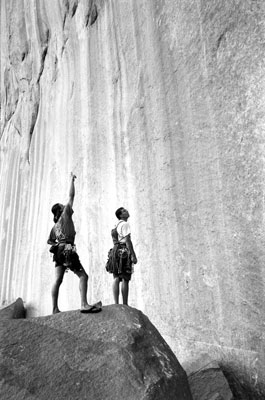

El Capitan's magic, 1997

How They Work

The main factors affecting nut performance are the nut's taper and the amount of surface contact it makes with the rock. The measure of a nut's performance is fit, security, and removability.

The taper (the angle between opposing surfaces of the nut as they contact the rock) is the primary parameter effecting all aspects of performance. The engineer's choice of this angle determines the trade-off between security and removability. A skinny angle (such as exists near the top of a curved nut) will not come out of a crack. A fat angle (near the bottom of a curved nut) will not stay in. Taper is felt to be so critical that Sentinel Nuts are designed with a specific, or "precise," taper that does not vary over the nut surface. Because of this precise taper security and removability are more predictable, more constant. Sentinel nuts are removable even after they've been weighted or fallen on.

Surface contact is also important. It is felt that both security and removability are enhanced when the area of contact between the nut faces and the rock surface increases. Taper, surface contact and fit coincide. If the taper is right a nut will fit the crack, be both secure and removable, and be easy to place.

USE: The theory is simple. The practice is not.

Assess the placement. The crack must provide adequate rock quality and constriction to resist pull-through in the direction of a fall, and adequate security to withstand dislodging forces. Check these attributes as you place the nut. In endwise placements, utilize the mild transverse taper to optimize the fit.

Set the nut well with strong jerks on the carabiner. Sentinel Nuts are designed to be removable after aid climbing and leader falls, so there is no reason not to set them well.

Add quick draws or runners as necessary to manage rope drag and prevent rope forces from dislodging the nut. In a fall, the rope will snap taut between neighboring protection pieces and can apply significant horizontal forces. Guard your protection line with securely set placements and adequately long runners.

The second climber can save wear and tear on the nuts' wire sling by using a nut tool to pop the nut up and out of the crack.

| Frostworks Home | Continue to Power Draws | Tom Frost Collection | Contact |